Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: RDGT

Brand: Ruide

Productivity: 15Sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 5Sets/Month

Certificate: ISO9001

Port: ShangHai

Payment Type: L/C,T/T

Incoterm: FOB

Multifunctional, capable of both lamination and drying

The application scope of the laminating machine:

Organic compounds: maleic anhydride, paraffin, asphalt, caprolactam, p-nitrochlorobenzene, catechol, p-dichlorobenzene, trimellitic anhydride, m-hydroxy, 1,8-diaminonaphthalene, diaminodiphenylmethane, N-phenylmaleimide, trimethylolpropane, polyethylene wax, polyvinyl acetate, TMP, polyformaldehyde, dodecahydroxystearic acid, triphenyl phosphate (TPP), MS, chloromethane, etc.

Inorganic:

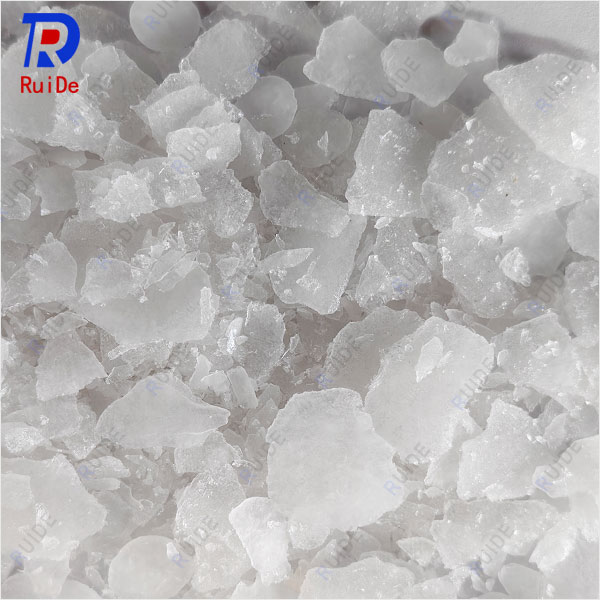

sulfur, alkali sulfide, carved white block, aluminum sulfate, calcium chloride, caustic soda, sodium hydrosulfide, etc

Fine chemicals:

4010NA, 4020, RD, DTPD and other antioxidants; Aflux, Aktipless, Z-80, plasticizer A, plasticizer B and other plasticizers, RC series organic cobalt salts, MOCA, leather treatment additives, surfactants, plastic additives, rubber additives, organic palladium salts, protective waxes, etc

Oil and chemical industry:

stearic acid and its salts, fatty acids (alcohols) and their salts, glycerides, DMP-100, rosin glycerides, palm oil, etc.

Resin category:

PF resin, tackifying resin, terpene resin, rosin resin, phenolic resin, polymerized rosin, epoxy resin, polyamide resin, petroleum resin C5-C9

Other:

hot melt adhesives, emulsion explosives, gelatin, beeswax, sodium fosilicate, thermosetting molding compounds, rubber plastic materials, vacuum bottom materials, electronic grade materials, MDA, DTPT, nitrocellulose fertilizers, nitrogen based composite fertilizers, PP | high concentration composite fertilizers, etc.

Product Categories : Grinder > Melt Granulation Machine

Home > Products > Grinder > Melt Granulation Machine > Drum laminating machine

Send Inquiry

Ms. Angel

Tel:86-519-68231907

Fax:86-519-68231871

Mobile Phone:+8615861192272

Email:sale@jsdryer.net

Address:Industrial Park Xinbei District, Changzhou City, Jiangsu Province, China, Changzhou, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.